As usual, as a person who is kepo and just needs to know, I spent quite some time bugging him to tell me what it was and to give me clues. Needless to say, he REFUSED to tell me anything and gave really vague and crappy clues. So all I could do was try to let it go and secretly hope that it would involve either food or a really good spa.

As the title states, it was neither food nor a spa. Instead, it was a Ring Making Workshop (insert big ass disappointed sigh here).

Arriving at their home studio in TTDI, we met the 2 owners of Materialise Creativity, Jane & Chin and we were then ushered into a room with a table looking very Transformeresque.

The entire workshop would take about 3 hours and was conducted by Chin.

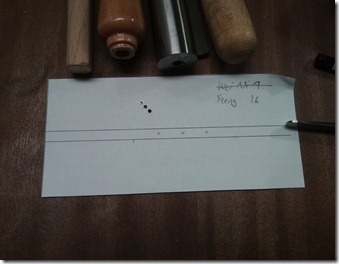

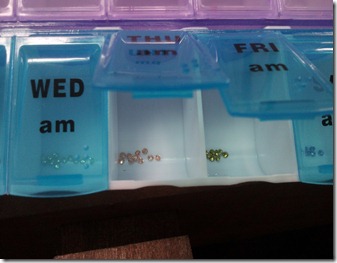

We were given a sheet of paper with 2 lines on it, that’s to show the thickness of the ring band. Then we were given a box of bling and asked to select 3 pieces and design them on the sheet of paper and mark the location where you want the bling to be. My BF thought it was a good idea for us to make the ring for the other person. I was frankly indifferent. In my head I was just thinking, WHY DO I HAVE TO MAKE MY OWN JEWELRY!

What's your drug?

If you’re wondering what this giant ring of rings is, it’s a ring measurer! Or at least that’s what I am calling it.

You slip your finger inside and look at the number on the ring and that’s your ring size. Mine is size 9 in case anyone feels like buying me a ring. :D

Literally, we had to make the ring from scratch. After getting our measurements, Chin then took out a long slim plate of 925 silver and proceeded to cut it according to our sizes. We were then asked to bend our ring into a circle. (Sorry no photos of this as I didn’t know we were allowed to take photos till later on.) Let’s just say ring bending is no easy feat.

Rings are then placed on a plate of stoned and soldered at 900degrees! Madness!

After soldering. There’s still an obvious line where the 2 ends were connected, but that will be fixed later on.

First we had to…

Place our ring into this gold measuring thing with numbers to check if the rings are correctly sized. And of course, they were not. They were in fact all ONE size TOO SMALL!

Into this thing it goes to knock it down to increase the size. Knocking away with a fat wooden stick.

Measure again, and repeat. It definitely took us awhile as we just couldn’t really get the hang of knocking the ring down.

My ruined nails from knocking. Was definitely not too pleased with this gift, especially since I just got them done a few days ago!

Next step, filing the ring to get rid of scratches and remove the soldering mark. Another long tedious process. With all these long tedious processes, I tried to do it as fast and as efficiently as I could. I just wanted to get it all over it to get to the end product!

From filing, we then had to do sanding. At least this was done with a machine and it was super easy and quick. Was rather fun using the machine!

Next on the list was polishing. We weren’t allowed to polish as it does get quite hot and if not done right it won’t look nice. Opportunity to slack off? No complaints from me!

Now that our rings were all nice and polished, we were then required to make small marks on the ring to indicate where we want the bling to be placed. Refer to top for ring design guidance. Not too sure if you can see the little marks on the ring above, sorry for the not so decent photos. Took them with my phone.

Next, Chin helped us to drill the holes for our bling. This needed precision and accuracy, so definitely not for newbies like us. And as usual, no complaints on my side!

Le holes for le bling.

Rings were then placed on this contraption, and we had to put the stones in one at a time. After each stone was placed, we had to use the tool in the right picture to press around the ring to set it.

Tadah! All the stones placed! Scratches at the side to be removed during final touch up by Chin!

And TADAH!

Finished product!

And umm… it wasn’t until I turned the ring to look at the holes inside that I realised that the marking I made for my BF’s rings were not even. One side is shorter than the other! Oops! At least it’s not my ring and the unevenness will not continue to bug me! Pleased!

From this:

To this:

In just 3 hours. Pretty hard to believe. Even I was shocked!

More info on who they are and what they do can be found at these links:

Website

Blog

Aside from holding workshops, they do accept custom orders as well. Refer to the above links for more info.

All in all, it was a rather interesting experience. Not too sure if I will go for another workshop, but I think I just might! The end product is kinda worth it. :)

So what’d ya guys think of the workshop and the finished product?

I think that this is something everyone should at least try once in their life, just to get a feel of how your jewelleries are all made. :)

Till next time!

xoxo

WN.

Ps: Just had to add, both Jane & Chin are immensely helpful and really nice! And I so very rarely like people!

No comments:

Post a Comment